RS TECHNIK Sleeve Pipe Rehabilitation Systems

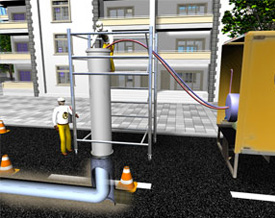

When an entire section of pipe is in poor condition, the repair/rehabilitation is carried out by introducing a sleeve impregnated with resin.

It starts from a sleeve composed of a fabric with a flexible plastic coating on one side. The sleeve fabric is impregnated with a mixture of epoxy resins.

The impregnated sleeve, still flexible, is introduced by inversion or pulling into the pipe, remaining adapted and glued inside. The resins are then hardened or cured by recirculating hot water, steam or UV radiation.

This creates a new pipe inside the original pipe, without joints, which guarantees its resistance and tightness for decades. All this without exterior works, without ditches or excavations and in a minimum work time, just a few hours.

RS Maxliner®

RS Cityliner®

Mobile equipment to carry out the entire process in the workplace.

No air pockets = higher degree of strength and dense laminated structure.

The mixing process is permanently and automatically controlled and guarantees constant product quality. Water pressure overturns the impregnated coating with a calibration roller speed of up to one meter per minute. The coating is reversed.

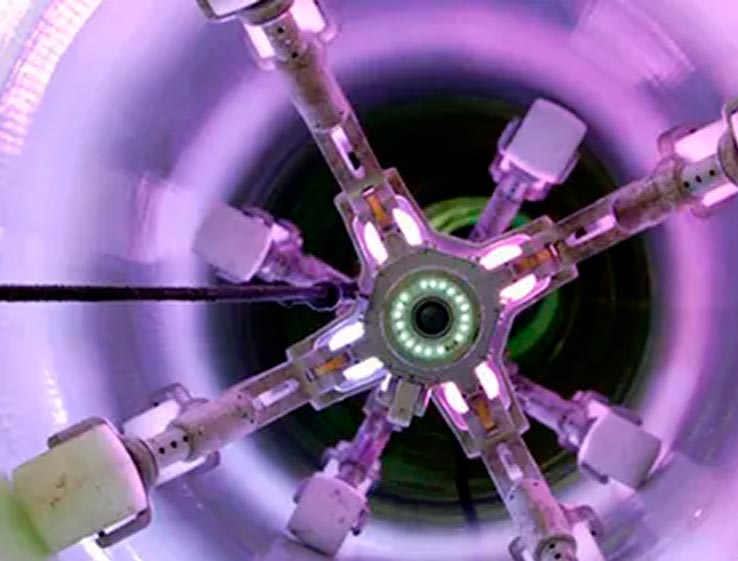

The house service connections are then opened quickly and accurately via RS cutters or robots.

After that, the home service connections are ready to work again.

Procedures and materials with certification for use in drinking water.

Different types of sleeves depending on the conditions of the pipe to be rehabilitated and special epoxy resins for on-site preparation.

Specific systems for installing sleeves impregnated with resins for curing using ultraviolet radiation.

Contact us

instagram.com/liningMéxico

instagram.com/liningMéxico

![]() administration@lininggroupamerica.com

administration@lininggroupamerica.com

© Lining Group America